Formerly considered as a simple carrier, the printed circuit board is becoming nowadays a smart device by embedding passive or active components. This new trend allows to increase the densification of interconnections. Fundamental research must anticipate this change from simple complex carrier to fully intelligent device. The LEM3 research team associated with this chair therefore offers a combination of skills to develop the following researches: • Identify the thermomechanical properties of materials used in the printed circuit boards, well beyond supplier datasheets.• Characterize the strength of interfaces, copper fatigue.• Predict the lifespan of multi-material assemblies, ever more complex, ever more smart.• Compare modeling predictions with tests on real configurations of printed circuit boards. The chair will benefit from the team’s expertise in modeling and digital simulation at the scale of the microstructure of materials, up to the structure of the printed circuit board. In support of this, the chair benefits from the equipment of the LEMCI platform (www.labcom-lemci.univ-lorraine.fr) and more generally of those of the LEM3.

Some examples of research conducted in 2020:

- Fatigue of copper

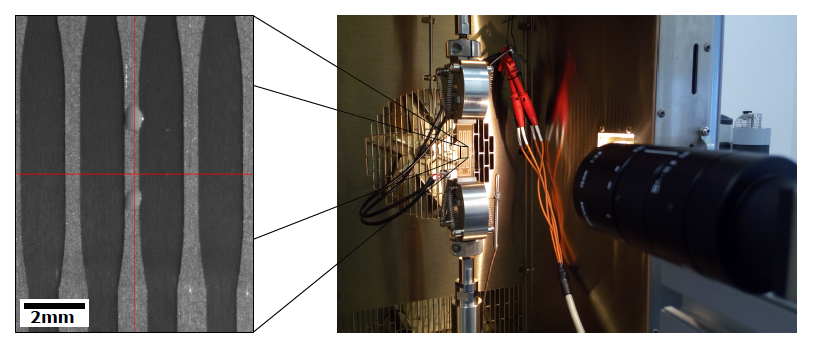

Predicting the lifetime of PCB requires a precise control of the elastoplastic behavior of copper and also its fatigue behavior. Indeed, during the life of any electronic product, the daylife operation generates a rise in temperature of the printed circuit board. The printed circuit board will undergo numerous temperature cycles and it is necessary to be sure that it will be in operating conditions during a time interval required by costumers in the initial specifications. Owing to experimental, numerical and theoretical developments, it was possible to measure the number of cycles to failure in terms of loading intensity. These results will feed numerical simulations of printed circuit boards to make them predictive.

|

| Experimental configuration developed within the chair to determine the fatigue life of copper path. |

The results have been presented at Eurosime 2020 (International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems).

- Flexible electronics

The chair has also developed works for flexible printed circuit boards. As the behavior of copper and its related fatigue was incestigated in the previous activity 1, we were able to conduct bending loading simulations and estimate the life of the configuration. One article is accepted in Microelectronics Reliability [2]. It is now necessary to compare the predictions of the model with real tests.

|

| Number of cycles to failre versus plastic strain amplitude. The results enable to identify the Coffin-Manson fatigue law. |

- Multi-scale approach for the predictions of the mechanical behavior of copper :

We have developed a micro-mechanical model for elastic-viscoplastic material (here for copper) based on microstructure characterization (texture, grain orientation, grain size, etc.). Microstructural information were obtained using dedicated characterization devices at LEM3 laboratory (SEM, EBSD, X-ray diffraction, etc.). From this information, the cyclic response of copper was reproduced with good accuracy. This work is the result of a collaboration with researchers (K. Kowalczyk-Gajewska and K. Frydrych from IPPT Warsaw, Poland). An article was recently submitted [3].

References :

[1] Gautier Girard, Marion Martiny, Sébastien Mercier, Elastoplastic and fatigue properties of copper in printed circuit boards: from experimental characterization to numerical simulations. 21st International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, EUROSIME 2020 Virtual event, July 2020

[2] Gautier Girard, Marion Martiny, Sébastien Mercier, Experimental characterization of Rolled Annealed copper film used in flexible printed circuit boards: identification of the elastic-plastic and low-cycle fatigue behaviors, Accepté dans Microelectronics reliability

[3] G. Girard, K. Frydrych, K. Kowalczyk-Gajewska, M. Martiny, S. Mercier, Cyclic response of electrodeposited copper films. Experiments and elastic-viscoplastic mean-field modeling, soumis à Mechanics of Materials.