Thermo-mechanical characterisation of base materials

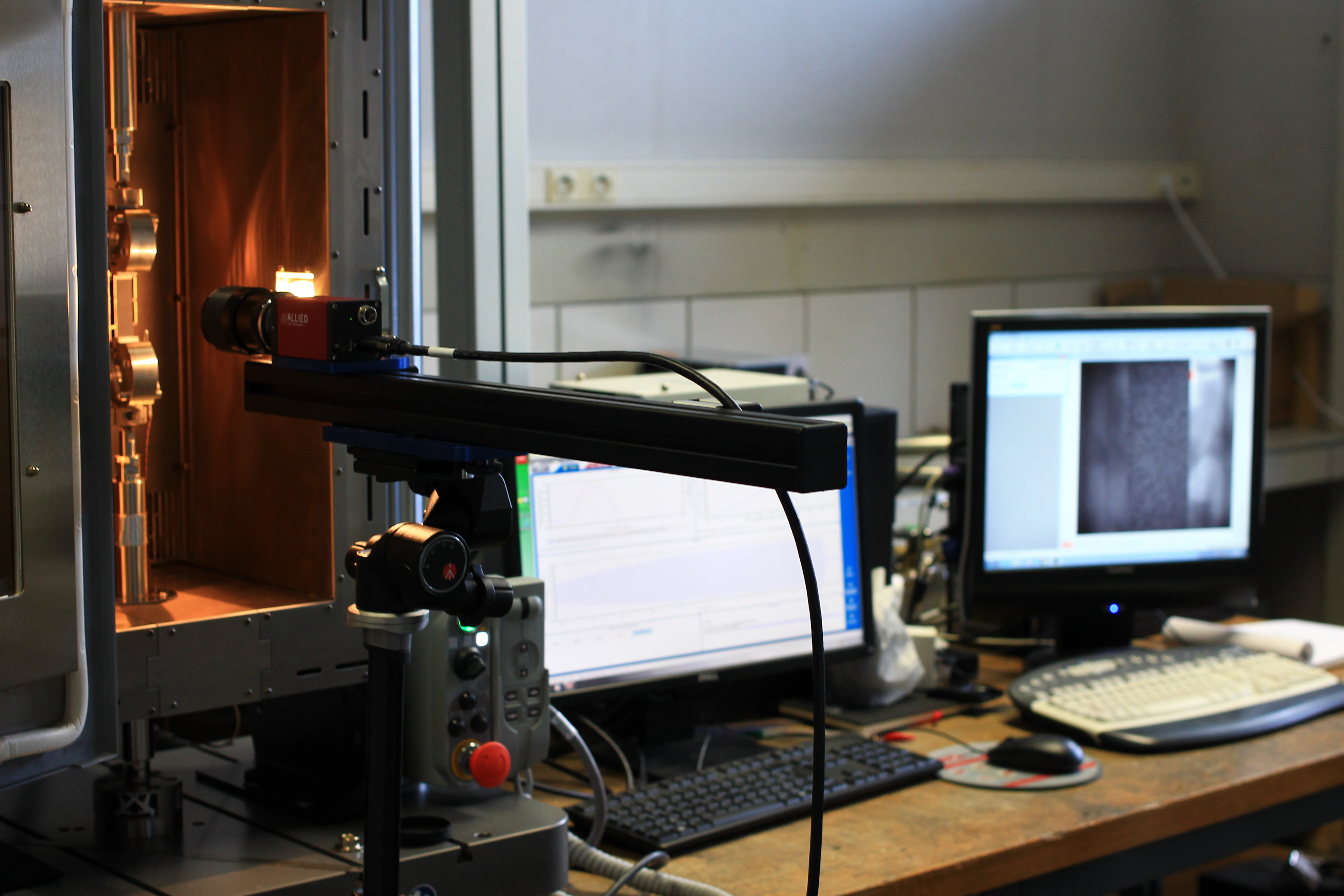

E3000 electropulse Instron device equipped with digital image correlation technique to capture strain maps, during testing E3000 electropulse Instron device equipped with digital image correlation technique to capture strain maps, during testing |

PCB are facing thermal loading during their service. So, to obtain accurate predictions of the lifetime duration, it is compulsory to determine the behavior of materials, not only at room temperature but also in the whole temperature range applied to the PCB. LEMCI has the capability to test thin films, as needed for PCB, but also the possibility for bulk materials, via the LEM3 partnership.

Thermo-mechanical behavior The pcb is made of layers (hundreds of microns thick) made of different base materials. Mainly, the elastic behavior of the ply is orthotropic. To identify the elastic moduli, tensile tests at various orientations are necessary. The electropulse E3000 Instron with a 1kN cell with a climate chamber (-80°C and 250°C) is dedicated for that purpose. We can also performed tests in dynamic conditions, up to 20 Hz. |

| Since the material is thin, a digital image correlation enables to measure displacement without contact. Such technique is also adopted with the climate chamber, due to a specific properties of the chamber window. The mechanical behavior of Copper is also investigated with this specific device. We have also developed a dedicated sample to identify and model the cyclic behavior of Copper. Indeed, the plasticity of Copper is crucial since copper will sustain plastic strain increment during each temperature cycle. A crack in the copper barrel will induce a lack of electrical connectivity and then the whole electronic device may be out of order. |

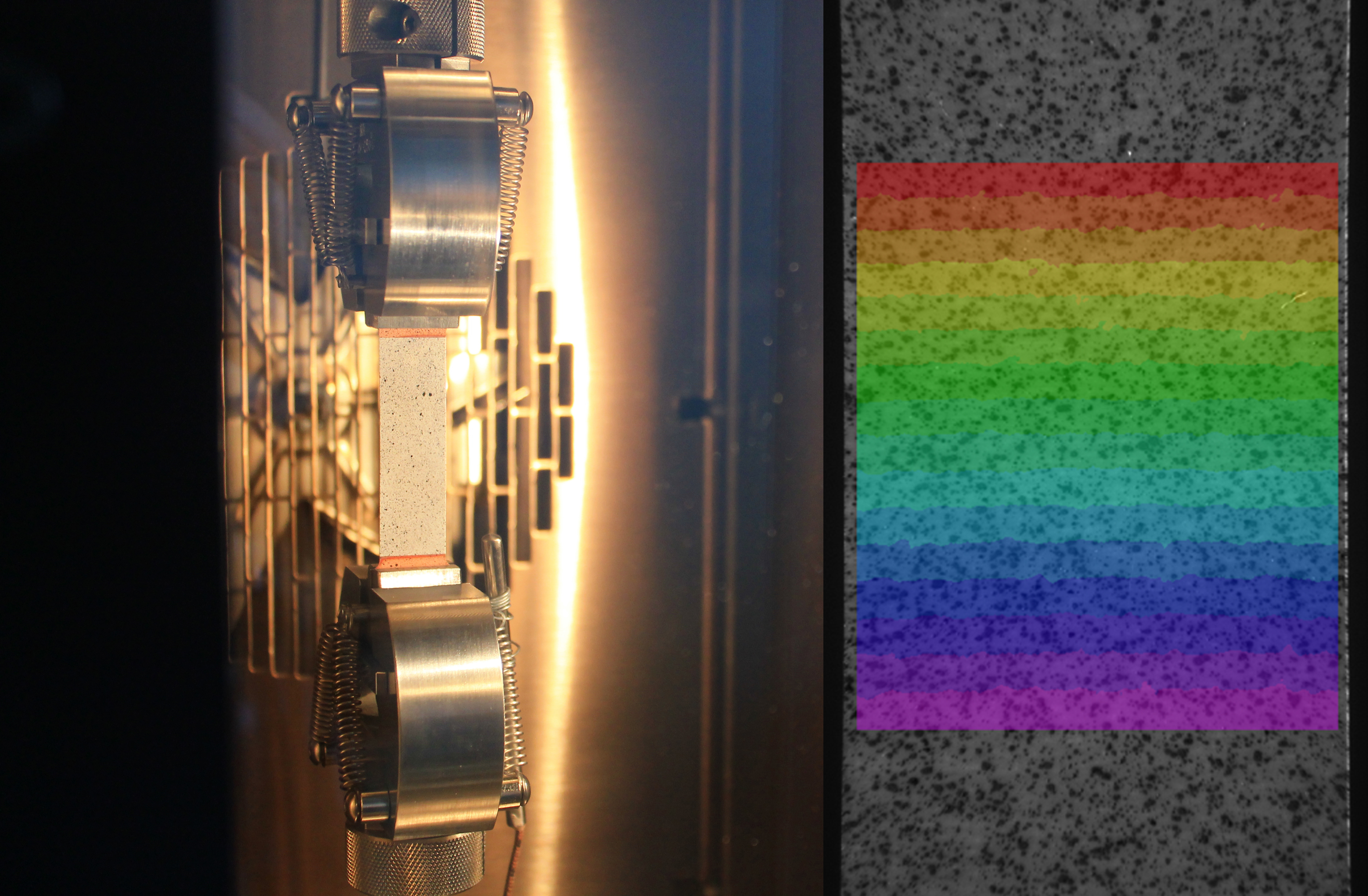

Left : Sample in the climate chamber. Left : Sample in the climate chamber.

Right : Horizontal lines representing iso-curves for the vertical displacement, are obtained via digital image correlation. The thichness of the sample is 100 microns |

Interfaces strength

Dedicated tensile device with a peel test. Note that the peel angle can be modified Dedicated tensile device with a peel test. Note that the peel angle can be modified |

Peel tests

Interfaces are numerous in a PCB. One can observe delamination between laminates, but also between copper and laminate. Peel testing is adopted in LEMCI to characterize the strength of the interface. Note that the angle for peeling can be varied to cover a wide range of configuration (from positive to negative angles). LEMCI can test all configurations that exit in a PCB. LEMCI has also a double cantilever beam for measuring more specifically the bonding between to resins or composite materials.

|

Microstructural characterisation

LEMCI can benefit from the facilities of LEM3 in terms of microstrutural characterisation. We can obtain high resolution images owing to up to date SEM, microtomography. The local texture of copper can also be measured via X-ray diffraction and EBSD technique. It is clear that the crystallographic orientations of copper may have a strong effect on the ductily of copper.

Virtual tour of our equipment dedicated to LEM3

View of our lab with thermo-mecanical devices used for our material characterization, at LEM3, click on this link to start the virtual tour of our equipment.